What is DRACO

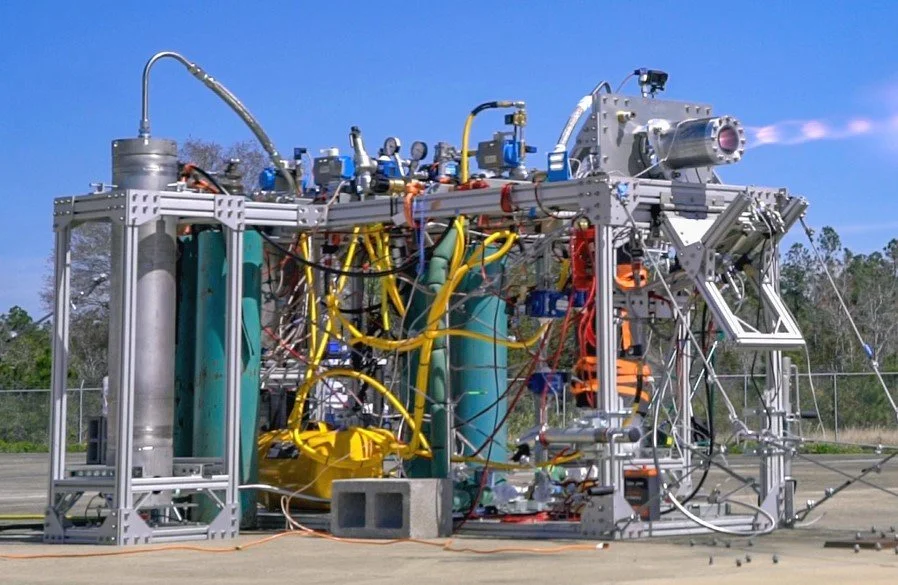

DRACO is the feed system that the Experimental Rocket Propulsion Laboratory(ERPL) uses to test and analyze various rocket engines. Using head-pressurized tanks, DRACO can supply numerous ambient liquid fuels as well as cryogenic oxidizers. This system not only allows the testing of engine hardware but also allows experimentation on fluid systems.

My Role with DRACO

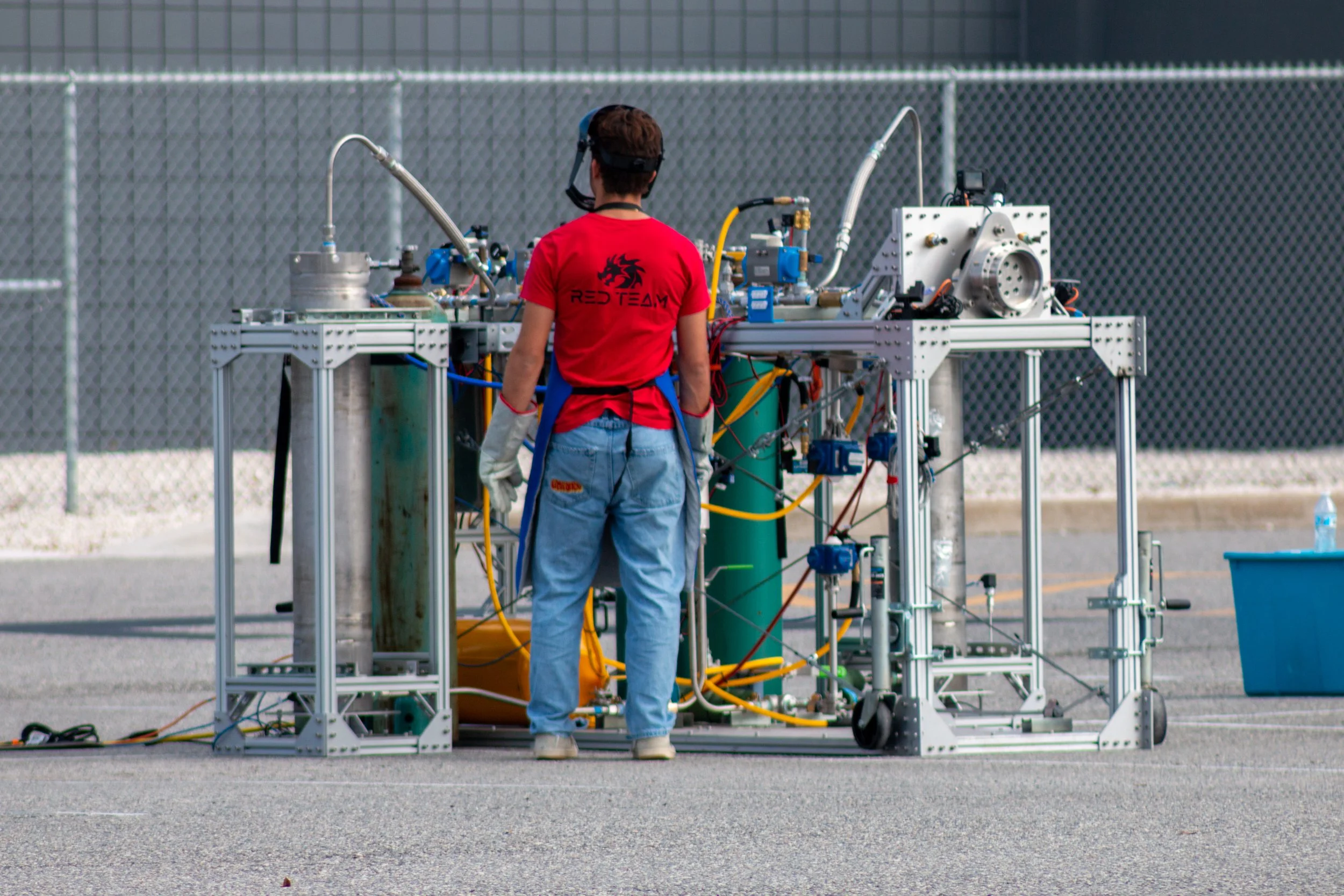

I design and assemble hardware across the system as changes or needed upgrades arise. I built a BOM to log, trace, and spec-check every DRACO part. As a member of RED Team, ERPL’s test operations group, I understand DRACO end-to-end and the rationale behind its design choices. That context lets me make informed, safe decisions in operations and engineering cleaner, more efficient assemblies.

Data Acquisition and Analysis

Defensibly, one of the most important things an engineer does is sound data analysis. That means not only understanding the system and how its data is collected, but also knowing how to use that data correctly and apply it empirically. I do both quick hand checks for single moments or short intervals and deeper analyses in Python and MATLAB scripts. I’ve written scripts that ingest large CSV/XLSX logs, automatically distinguish hot-fire versus water-flow runs, and return the metrics I need so decisions are grounded in clean, defensible evidence.

Status of DRACO

DRACO is still ERPL’s primary means of testing our engines. However, we have a few fluid systems either built like the simple waterflow setup or currently in construction, like the vertical test stand. For the foreseeable future, we will continue to use DRACO for engine testing and analysis, especially for upcoming engines such as my project Saguaro, a composite engine, and RED, our regen development engine.